First Run

From project submission to engineering support to manufacturability, let our experience identify supply chain challenges, navigate internal and external time constraints, and develop a shared plan to deliver a first run of your parts efficiently and without setback.

Bring your team to meet our team and co-develop your plan with us in our newly built Manufacturability Center.

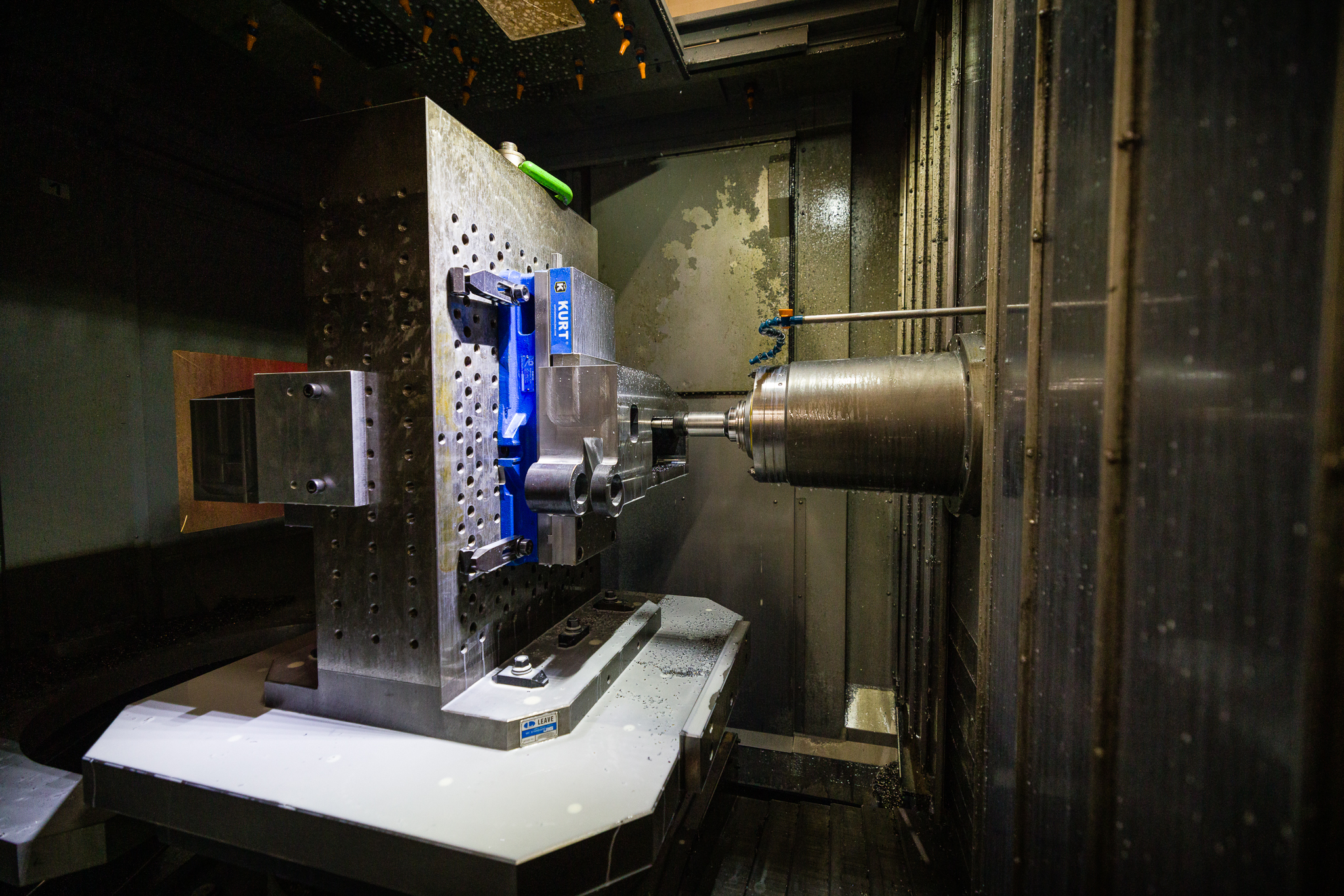

You have the design. We have the technology , the skill, and the supply chain

A solid model and a bill of materials will get our team started on planning your custom manufactured first run of parts. We can meet remotely or at our Manufacturability Center to talk through fit, form, and function as well as timelines, roles and responsibilities.

Receive the engineering and manufacturing support you need with your quote in a timely manner. Once you send the PO, you’ll receive the transparency and consistent communication you need throughout the project life cycle.

When design meets Fit, Form, and Function in the real world

Engineering changes, print revisions, unforeseen supply chain delays, and unnecessary tolerances. They always happen.

With expertise, experience, and the world largest tool boxe, you have a partner that is committed to maintaining your timeline for the first run of parts.

Responsiveness and agility are two of our most important values. As your project progresses and we find conflicts, you can be sure we’ll contact you with suggestions and solutions.

You are welcome and anytime to visit the progress of your project and you might even be invited to work through the solutions together as necessary.

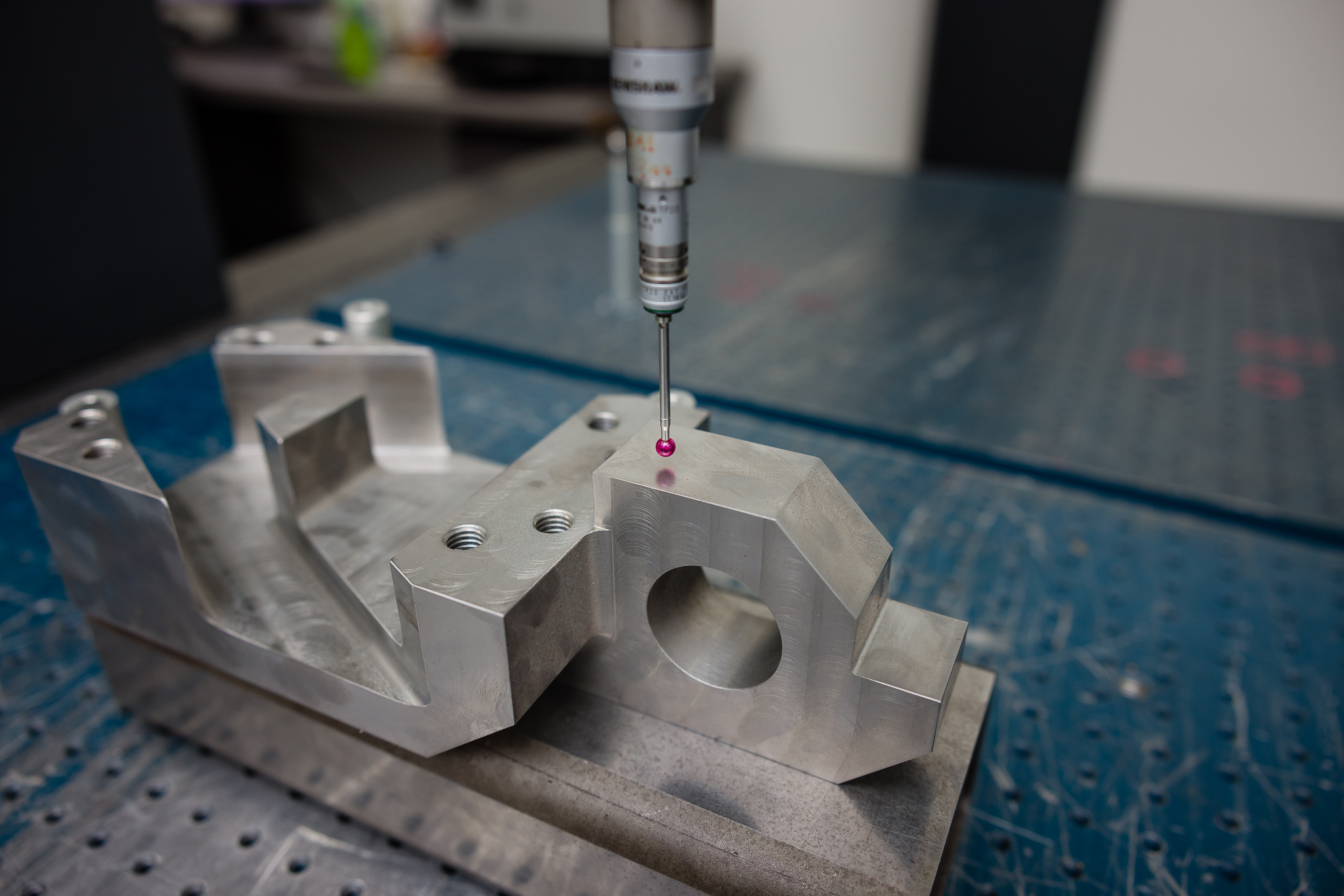

Proof of talents, not just concepts.

Because general machining and manufacturing principles can have subjective meaning, part of your first run of parts my call for material certifications, service certifications, and a full CMM inspection report.

Upon completion of you first run, we are available to meet with your team to discuss red line prints and revisions so you can update your CAD and Solid Models.

To assist with efficient quoting, please submit your inspection requirements with your RFQ.