Repair and Rebuild

Just recently, we saved the power grid, opening day, a brewery, the MKE Bucks training facility, a historical railraod train, and a ships mooring capability.

Customer of every market segment and product category trust us to repair and rebuild their OEM equipment that still adds value to their business.

Feel free to schedule a tour to view our capabilities and meet the skilled team that will be working on your projects.

Scroll down for more information or submit you Request for Quote to get started.

Repair of Packaging, Processing, and Printing Equipment.

Latest project include:

- Saving cheeseburgers everywhere by grinding of carbide cutting wheels for sliced cheese packaging equipment.

- Saving opening day by repairing an auger assembly for a sausage maker.

- Reworking a hole pattern for adjusting one of the Milwaukee Bucks pieces of training equipment.

- Saving the power grid for WE Energies with a custom shim.

- Rebuilding a pneumatically controlled coil winder.

Repair of Hydraulic Fixtures, Recycling Equipment, and Assembly Equipment.

Latest projects include:

- Reworking a hydraulic powered base plates for natural gas distribution engines.

- Upgrading of tooling and installation kits for MRI equipment.

- Spray weld and grinding of feed rolls and crushers for the recycling industry.

- Reworked weldment and bore placement for gearbox housing.

- Repair and replace hole patterns in frames for recycling equipment.

Repair of Gearbox Housings, Mixing Equipment, and Looms.

Latest projects include:

- Repair of hole pattern for pill coating machinery.

- Increase bore sized for wind energy gearboxes

- Straightening of framework for architectural wire loom.

- Machine mounting holes for draw bridge mating plates

- Rework hole pattern for margarine processing equipment.

- Rework frame and tooling for machining fixture for the agricultural equipment manufacturer.

- Reverse engineering of legacy parts for soda bottling equipment.

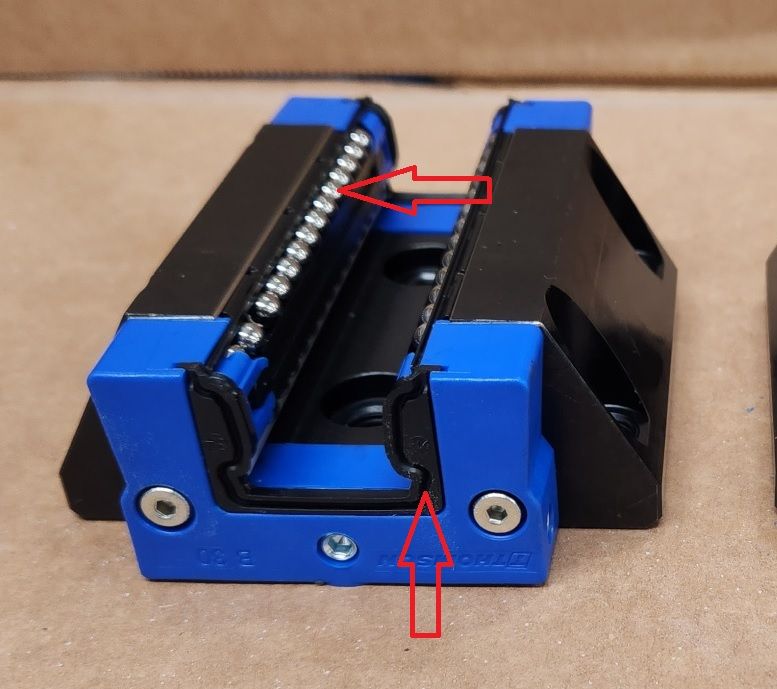

NEW Low Friction Polymer Material Solutions (LFPM) Solutions.

Allis Manufacturing acquired SlideTech LLC in December of 2022 to expand our repair services for linear motion applications. This allows engineers to change parts without changing the overall design.

Latest projects include:

- Replacement of ball bearings and wipers for Thompson, THK, and Misumi Linear Guide in 20mm and 30mm rail sizes.

- Replacement of slide nuts for lead screws

- Custom slide blocks to replace OEM guides that continuously failed.

- Upgrades of OEM guides for custom burn table manufacturer.

You can learn more about specifically about our drop-in LFPM No-Lube Linear Motion Guides, Lead Screws, Slide Nuts, and Slide Trucks at the SlideTech website.